Wire and Cable manager

General

Cable Manager provides route optimisation functions, for wires and cables.

These functions can:

-

Reduce your Cable and Wiring materials estimation error to +/- 5%.

-

Automatically route wires and cables via optimum routes (less cable required).

-

Report all routing of cables and wires.

-

Report all cable and wire lengths.

-

Report, for maintenance purposes: Cross-sections of cable raceway in a plant.

-

Report: Missing panel duct and raceway segments and routes, redundant segments and routes, devices and panels which are not terminated / fed, raceway which is over filled or under filled etc. (Reducing estimation error and re-work).

Route Optimisation Preparation

Prior to running the Route Optimisation Process on your model, you should prepare the list of items shown below to achieve the best outcome and reduced errors.

Preparation for Ductbank Editing

The ductbank editor can provide a cable cross section of the trench. To achieve this, the cables must be routed through the trench rather than through any ductbank conduits already placed in the trenches. You should tick the option: Hide Ductbank Conduits in the above procedure to force the route optimisation to use the trenches.

Procedure

-

Select the Cable Manager entry from the Routing: Wire and Cable menu.

-

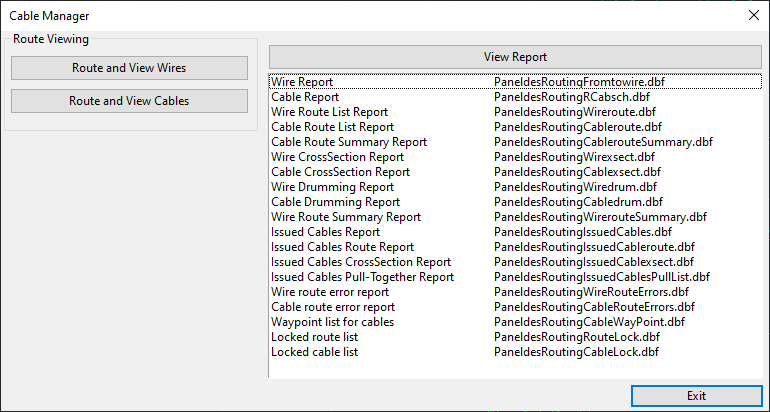

You will be presented with the Cable Manager Dialog shown below.

-

For Routing and Viewing Wires on your Paneldes Model click on the button click on button .

-

For Routing and Viewing Cables and advanced features like Waypoint selection, cable modification, cable drawing click on button .

-

For viewing a Cable/Wire report, select the report from the list of reports and click on button .

Route Reports

The route optimisation process updates or creates various DBF format report files.

See Also

How does the route optimisation function work.

How to Tune Your Model for Wire and Cable Routing.

How to route wires on multiple panel models.

How to View Wire and Cable Routes.