How to Route and View Wires and Cables

General

The Cable Route Display dialog is allows you to route, view, select waypoints, and modify your conductors (cables / wires). Cable or wire routing runs the route optimisation process and provides you with diagnostic information for tuning your model.

The viewing functions allow you to visualise the routes that have been calculated by Paneldes.

The options for cable routing differ slightly from the options for wire routing.

Procedure for Cable routing

-

Click the button in the Cable Manager dialog. Cable Manager can be accessed from the Routing: Wire and Cable menu.

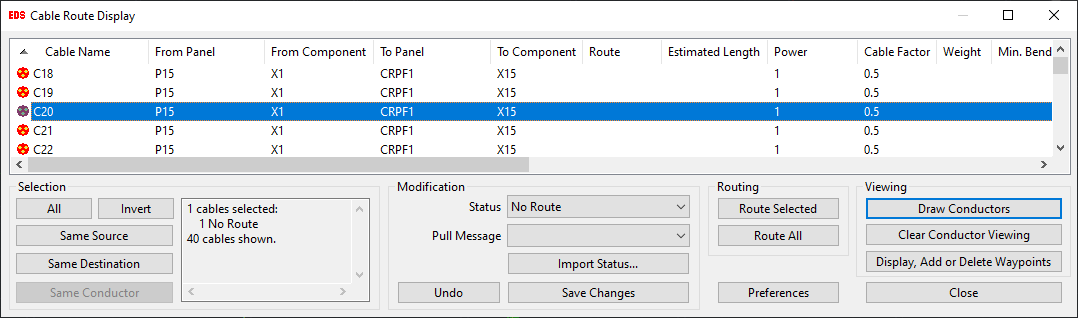

You will be presented with the Cable Route Display dialog as shown below.

-

Click the button to set appropriate routing settings for your model in Paneldes preferences.

-

You can use the selection buttons along the top of the dialog to select a group of cables for routing.

-

Once your cables are selected you can route them by clicking on . Alternatively, click to route all of the cables regardless of which are selected. This will run the Route Optimisation Process for each cable and updates or creates various DBF format report files.

-

Paneldes will present you the Route Optimisation summary. Press OK if you are satisfied with the Routing Summary, otherwise you can tune your model and run cable routing again.

-

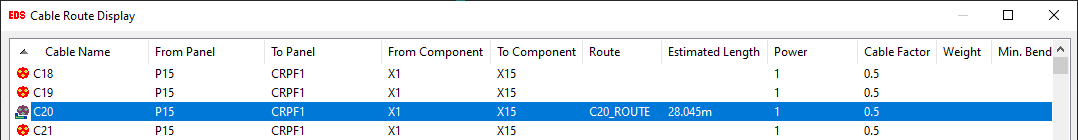

Once routing is finished successfully, you will notice that the Route Column is updated with a cable route name for each cable that was routed successfully e.g. C20_ROUTE as shown below.

You will need to check that your cables are in the appropriate trays, conduits etc. and that the routes found by Paneldes are suitable.

You can check your cables by drawing and viewing them by clicking on button for the cables selected in the list. Terminating devices or panels will be drawn even if there is no route found for the cable.

You can remove/clear all the conductors drawn on your model by clicking on button.

You can query the waypoint segments of a selected cable and choose to modify the waypoints by clicking .

You apply various modifications to your cables e.g. changing cable status, setting a pull message etc. click here to find How to modify your cable(s) status.

Pressing the button will undo the recent change(s) made to your cables. Every time you press the Undo button it will step back to the previous change you made to the cable list.

Pressing the button will save all the modifications that you have made to your cables list using the cable route display dialog. Paneldes will ask you to save any unsaved changes before exiting the cable route display dialog as shown in the image below.

Procedure for Wire routing

-

Click the button in the Cable Manager dialog. Cable Manager can be accessed from the Routing: Wire and Cable menu.

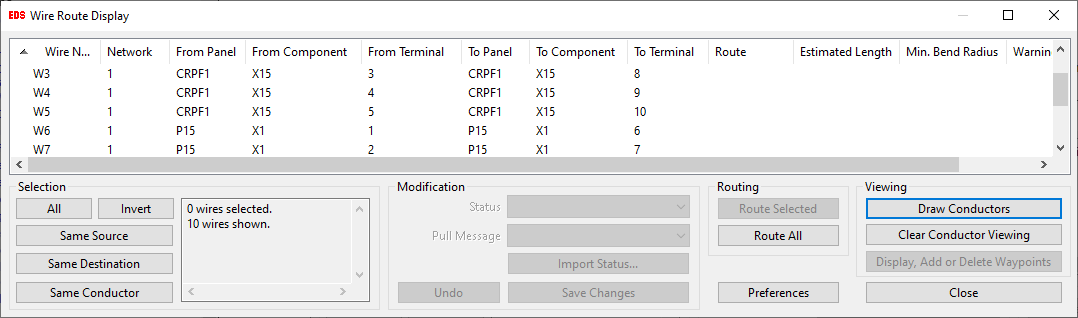

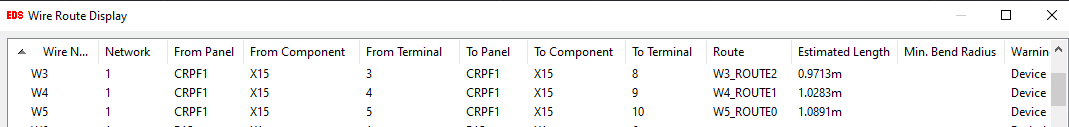

You will be presented with the Wire Route Display dialog as shown below.

-

Click the button to set appropriate routing settings for your model in Paneldes preferences.

-

You can route your wires by clicking on .

This will run the Route Optimisation Process on all of the wires and will automatically update or create various DBF format report files.

If you are have more than one panel drawing in your project, you will need to avoid Paneldes overwriting results when each drawing is routed. See: How to route wires on multiple panel models

-

Paneldes will present the Route Optimisation summary. Press OK if you are satisfied with the Routing Summary, otherwise you can tune your model and run wire routing again.

-

Once routing is finished successfully, you will notice that the Route Column is updated with a wire route name for each wire that was routed successfully e.g. W3_ROUTE2 as shown below.

You will need to check that the wire routes found by Paneldes are suitable. You can check your wires by drawing and viewing them by clicking on button.

You can remove/clear all the conductors drawn on your model by clicking on button.

Notes:

-

It is very important to note that when you modify the status of a cable to ISSUED or PULLED, it may impact the routes of other cables ( i.e. the cables which are using the same route but not ISSUED or PULLED yet ).

Therefore, to avoid any inconsistencies with cables that are not ISSUED or PULLED, you must run the routing again on all of the cables once a cable is ISSUED or PULLED.

-

You must run the routing functions before using the viewing functions re. the routing process.

-

During viewing, many of the Paneldes layers are automatically turned "off" for visual clarity. Use the Clear Routes button inside Cable Manager to return to a normal model view.

-

During viewing, cable and wire routes are drawn on the Paneldes "routedisp" layer.

-

During viewing, the "Construction" layers for raceway envelope are left visible so you can view the raceway that the conductor is routed through.

-

Labels are attached to the lines of the viewed route to identify the conductor.

-

The line for the conductor route is drawn with a non-zero lineweight to enhance visibility.

-

If cables are drawn as solids, the diameter of the cable is obtained from the first of the cable catalog columns: OD, DIAM, DIAMETER, OD_DIAM or ODIAMETER that contains a value.

-

You can query a conductor after you have used this tool to view its route.

-

Raceway segments from locked routes that are missing from the model will be skipped when viewing the route. The straight line across the gap vacated by the missing segment will be used in its place.

See also

How to Configure the General Settings

How to Configure the General Routing Settings

How to Configure Cable Routing Settings

How to Configure Wire Routing Settings

Route optimisation errors and warnings

How to route wires on multiple panel models.

How to route cables from a single project on multiple workstations

How to use the NEC code to calculate raceway fill for trays and conduits.

How to Draw a Route Segment Cross Section Table.

How to Tune Your Model for Wire and Cable Routing.

How to Optimise the Termination Order for Wires.

Route List Diagnostic data ( RLIST.TXT )

Segment to Panel Connection data (SegToPanelConnections.txt)